The 300,000-ton SPM system in Maoming is classified as a CALM system. The configurations of a CALM system are as follows:

1. Structure types of CALM single point

CALM is the first and the most distributed single-point mooring system in the world. At present, there are more than 500 CALM systems worldwide.

The characteristic of this type of single point mooring is that the buoy is a single point mooring device which is fixed to the anchor or is piled on the seabed with a number of radially-arranged catenary anchor legs (generally through anchor chains) and the buoy is connected with the submarine manifold by flexible pipes.

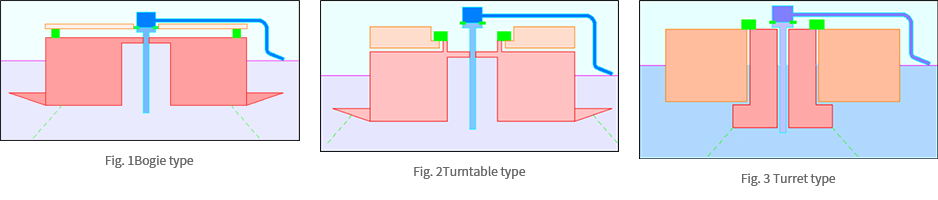

Nowadays, the CALM technology has developed and become a relatively mature technology, which is now could be divided into several typical types. There are three types of CALM based on their structures: Bogie type, Turntable type, and Turret type (enclosed with Figure 1, 2, 3).

The structure of Bogie type is similar to that of the Turntable type, whose Buoy Body is fixed with anchor chain connection. The difference between these two is that the three-arm rotating plat form of the Bogie type is supported by the main slewing bearing and roller track, while the one in the turntable type is completely supported by the slewing bearing.

Nevertheless, in Turret type buoy, the top part of the buoy body could rotate freely, which makes the Turret type unique to the above two types.

2. Components of CALM single point

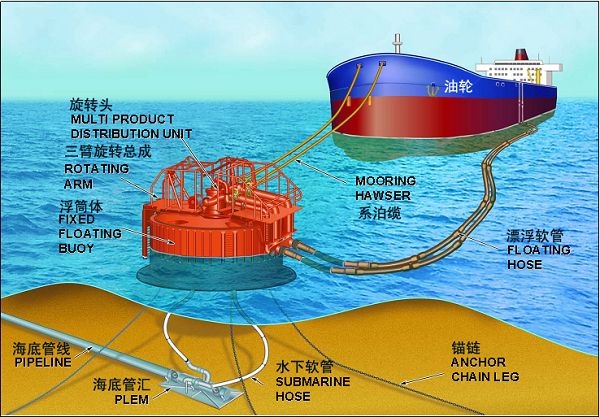

CALM single point is mainly composed of buoy, floating hoses, submarine hoses, mooring system, submarine pipeline (including submarine manifold) and mooring assembly, as shown in Figure 4.

Fig. 4 Schematic diagram of Calm System

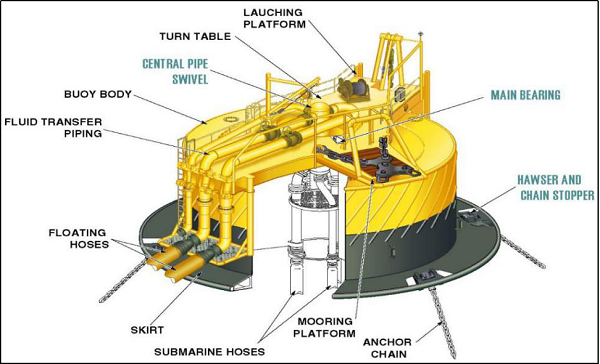

1)Buoy Body

A single point buoy is used to provide positive buoyancy and is a prerequisite to install a rotating device. The size of the buoy depends on the required positive buoyancy and other structural requirements. In addition to strength requirements, the buoy body must also meet water stability requirements, including stability in both chainless towing and in maximum external environment. The structure of buoy is shown in Figure 5.

Fig. 5 Schematic diagram of CALM rotary buoy

2)Floating Hoses

A floating hose is a junction between the buoy oil platform and the manifold of the tanker. For the convenience of installation and storage, the hose is designed based on a series of sections, in which each section is about 10 meters long, and connect to each other to be a bulk chain, as shown in Figure 6.

Fig. 6 Floating Hose of CALM system

3)Submarine Hoses

The connection mode of the submarine hose is similar to that of the floating hose, one end of which is connected to oil pipeline at the bottom of the buoy, and the other end is connected to the submarine manifold.

There are three commonly-used configurations for submarine hoses: Chinese Lantern, Steep waves and Steep “S”, as shown in Figure 7.

Fig. 7Chinese Lantern, Steep waves , Steep “S”

4) Mooring system

The mooring system is composed of 6 to 8 Hub-and-spoke chains with the buoy as the center. The anchor chain connects the buoy to the seabed-anchor-pile to fix the buoy on the sea surface, preventing the buoy from excessive displacement.

5)Submarine pipelines and manifold

The submarine pipeline and the SPM submarine hose are connected through the submarine manifold, and the other end of the pipeline is connected to the onshore oil depot to transport the crude oil and other liquid cargo.

Generally, two sets of hydraulically driven valves will be installed on the submarine manifold to isolate the hose and pipeline. and to prevent the oil emission to the environment when an emergency occurred.

Fig. 7 Submarine manifold of CALM system

6) Mooring Hawser

The mooring hawser is composed of buoy transition chain, mooring hawser, friction chain and pickup line, etc. It is used for attaching the single point buoy when the tanker is mooring at a single point, so that the tanker can rotate 360° around the buoy under the force of winds and waves.

CALM type SPM oil unloading process: tanker → floating hose → buoy oil arm → buoy MPDU → submarine hose → submarine manifold → submarine pipeline → onshore oil tanks.

Similarly, if the shore oil tank is equipped with the loading system, the crude oil can be loaded to the oil tankers through the SPM system. Thus, a simple SPM terminal can make a crude oil tank a base for crude oil transfer.